Customer Order Processing (ERP)

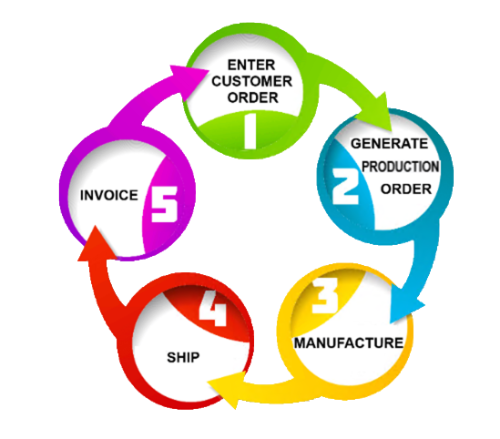

From Purchase Order to Packing List and Invoicing, Customer Order Processing is the end-to-end ERP workflow that manages customer orders across sewn products, furniture, mattress, and athletic goods manufacturing. BYTE’s system supports complex style–color–size (SCS), dimensional, and lot-based requirements — from order entry through production, shipping, and billing. ...

Key Processes

Overview

Customer Order Processing is the end-to-end ERP workflow that manages a customer’s purchase from order entry through production, shipping, invoicing, and delivery. For sewn products manufacturers, this process must accurately handle products by style, color, and size to ensure correct fulfillment and production alignment.

BYTE’s Customer Order Processing module is designed specifically for apparel, uniform, and soft-goods manufacturing environments. Orders are entered, tracked, and fulfilled at the style–color–size level, improving accuracy, reducing errors, and providing real-time visibility across sales, inventory, production, and shipping.

BYTE’s Customer Order Processing provides seamless integration between the front office and the shop floor, ensuring that customer demand directly drives production and fulfillment.

Key Capabilities

Industries We Serve

BYTE’s Customer Order Processing ERP is trusted by manufacturers producing complex, configurable products that require precision from order entry through fulfillment.

- Sewn Products & Apparel

- Furniture & Upholstery Manufacturing

- Mattress & Bedding Manufacturers

- Athletic & Sporting Goods (including ball manufacturing)

- Assembly-Line & Cut-and-Sew Operations

Benefits for Sewn Products Manufacturers

- Accurate order processing by style, color, and size.

- Automate customer orders into production orders.

- Improve production planning using real-time SCS demand.

- Reduce shipping errors with barcode-based fulfillment.

- Handle high SKU volumes common in apparel manufacturing.

- Improve on-time delivery and customer satisfaction.

- Reduce manual data entry and administrative overhead.

- Gain visibility into sales performance by style and size.

- Support Make-to-Order and Make-to-Stock environments.

- Shorten the order-to-cash cycle.

Let's walk through BYTE's ERP live.