Quality Control Solutions

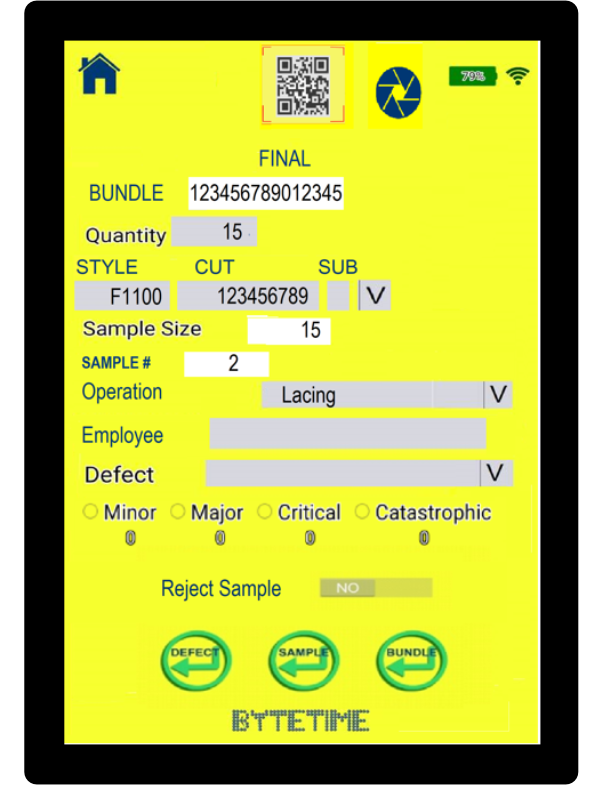

Byte’s Quality Control Solutions takes the mystery and angst out of your quality control issues. As an add-on package to our BYTETIME Shop Floor Control System, this software uses wireless technology to provide a real-time solution that helps reduce administrative time spent documenting quality problems on the sewing floor. Our Block Inspection program allows for “final” type inspections to be done in-line.

Features & Benefits

- Strengthen process controls to drive increased efficiency and productivity.

- Track and meet compliance requirements which imptoves customer satisfaction, loyalty and additional business

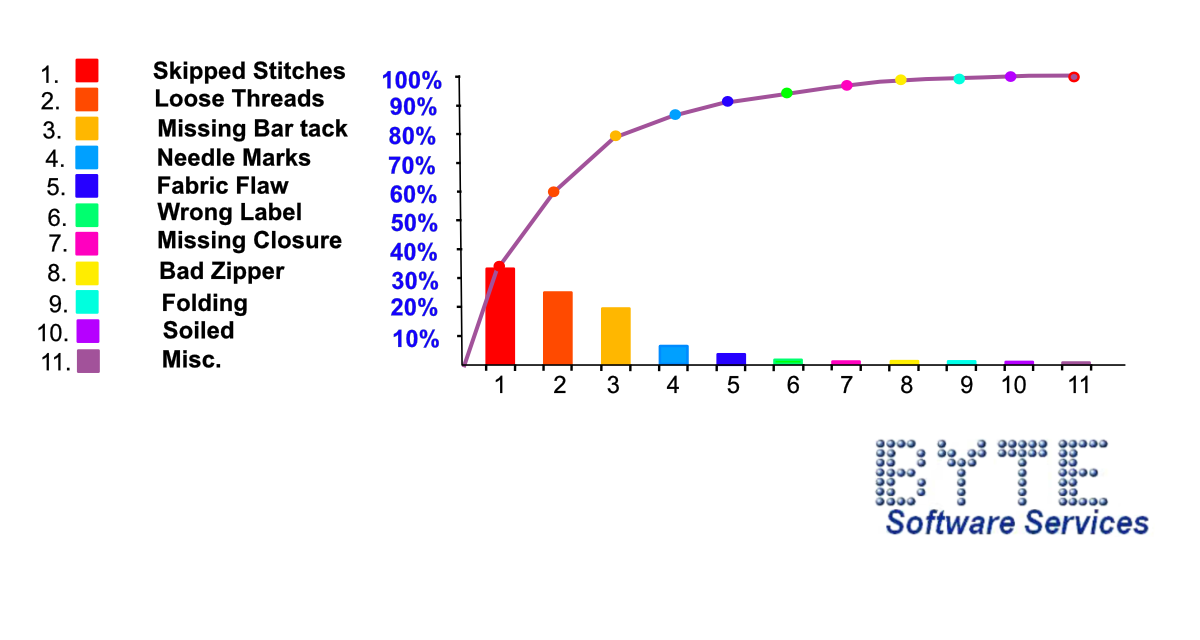

- Reduces Cost of Quality (CoQ) by reducing the labor requirements in the quality department and ultimately fewer defects and repairs ond returns.

- Provides increased labor productivity by making personnel more conscious and understanding of how information is used and its importance to quality production and job security.

- Dramatically Reduce Clerical Time by eliminating the need for auditors to record data other than the initial notation.

- Reduces paperwork, saves time and eliminates errors through wireless barcode data scanning on the plant floor.

- Provides faster troubleshooting for corrective action as the software eliminates lag time between identifying defects, understanding the problem and taking corrective action..

- Customized AQL Tables let you tailor your quality process for each customer.